What tells the labeling about products?

Laser protection eyewear

On laser safety filters the protection levels of the applicable standard must be permanently marked.

Laser adjustment glasses:

The marking of laser adjustment glasses indicates the following characteristics of the product: Laser power or pulse energy, wavelength, protection level (RB) according to DIN EN 208 and other manufacturer's specifications.

Laser protection barriers/laser protection windows

The marking of laser protection barriers and windows according EN 12254 indicates the following characteristics of the products:

Work protection eyewear

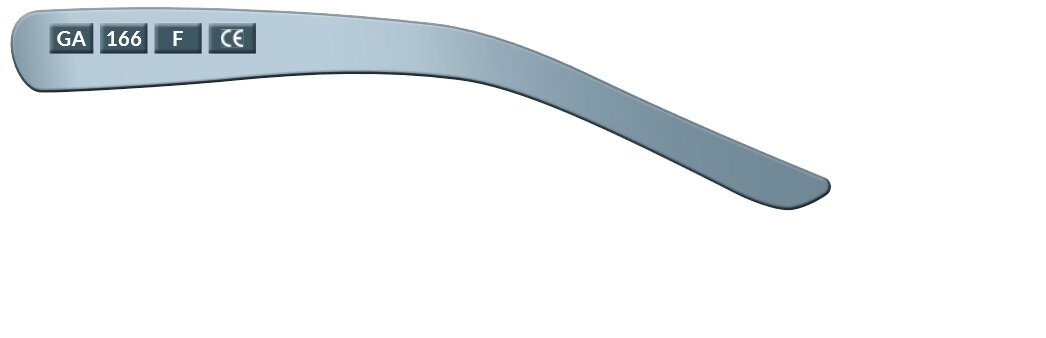

You can see the spectacle frame marking printed clearly on the frame itself. It is only valid with the CE quality mark.

|

Spectacle-frame product coding |

|

|

Mark |

Meaning |

|

GA |

ID mark of the manufacturer INFIELD |

|

166 |

Number of Norm EN DIN 166 |

|

S oder F |

Mechanical strength |

|

CE |

Conformity mark |

Work protection eyewear

Safety lens marking

The engraving on the upper edge of the safety lens contains only the most important information, so as not to obstruct the field of vision.

|

Safety lens product marking |

|

|

Mark |

Meaning |

|

2C – 1,2 |

Filter/tint protection grade |

|

GA |

ID mark of the manufacturer INFIELD |

|

T |

Mechanical strength in extreme temperatures |

|

1 |

Optical class |

|

S oder F |

Mechanical strength |

|

K |

Resistance to scratches |

|

N |

Anti - Fog |

|

CE |

Conformity mark |

Scheibencodes Arbeitsschutzbrillen

| Lens code | Name | Material | Colour | Coating | UV Protection | Light transmission | Lens coding |

|---|---|---|---|---|---|---|---|

| 006 | PC HC AF AS UV | PC | Clear | Clear HC AF AS | 100 % | 91 % | 2C-1,2 GA 1 F K N CE |

| 105 | PC HC UV | PC | Clear | Clear HC | 100 % | 91 % | 2C-1,2 GA 1 F K CE |

| 155 | PC AF AS UV | PC | Clear | Clear AF AS | 100 % | 93 % | 2C-1,2 GA 1 F N CE |

Coating technology

CLEAR HC = Hard Coating (HC)

This special lacquer coating greatly enhances scratch-re-sistance on both surfaces of the lens. The hard layer also improves protection against chemical attack.

CLEAR AF AS = Coatings Anti Fog (AF) und Anti Statik (AS)

This coating makes safety lens scratch-resistant, anti-fog and antistatic on both the inner and outer surfaces. In particular, a combination of anti-fog and anti-static effects ensures clear vision for long periods. The lens surfaces remain dirt-free for longer and are more easily cleaned.

CLEAR AFP = Coatings Hard Coating (HC), Anti Fog (AF) und Anti Statik (AS)

The perfect coating combination of INFIELD CLEAR HC and CLEAR AF AS with enhanced scratch-resistance and anti-fog on both the inner and outer surfaces of the glasses. This improved anti-fog effect ensures that the glasses are fog resistant even with extreme temperature fluctuations. The enhanced scratch-resistance provides greater protection from external effects.

Designation (abbreviation): UV

INFIELD Safety safety lenses marked ‘UV’ absorb 100% of UV rays that damage the human eye.